|

Symbolism and Cultural Significance

The Loom is a symbol of cosmic creation and the structure upon which individual destiny is woven. This symbolism is encapsulated in the ancient Greek myth of Arachne who was changed into a spider by the goddess Athene,who was jealous of her skill at the godlike craft of weaving. In Maya Cultures the goddess Ixchel who is symbolized by the moon, taught the first woman how to weave at the beginning of time. (Source: Wikipedia)A woman would sit here for many hours, and usually had a wider amount of threads across (I never can remember which is warp and which is woof.)

Handloom The Korkosz Croft in Czarna Góra, Poland, Nineteenth Century

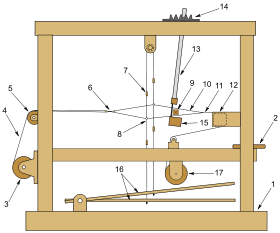

| Elements of a foot-treadle floor loom |

|

I'll let you read what it says now...

Weaving

The major components of the loom are the warp beam, heddles, harnesses or shafts (as few as two, four is common, sixteen not unheard of), shuttle, reed and takeup roll. In the loom, yarn processing includes shedding, picking, battening and taking-up operations. These are the principal motions.

- Shedding. Shedding is the raising of part of the warp yarn to form a shed (the vertical space between the raised and unraised warp yarns), through which the filling yarn, carried by the shuttle, can be inserted. On the modern loom, simple and intricate shedding operations are performed automatically by the heddle or heald frame, also known as a harness. This is a rectangular frame to which a series of wires, called heddles or healds, are attached. The yarns are passed through the eye holes of the heddles, which hang vertically from the harnesses. The weave pattern determines which harness controls which warp yarns, and the number of harnesses used depends on the complexity of the weave. Two common methods of controlling the heddles are dobbies and a Jacquard Head.

Shuttles

- Picking. As the harnesses raise the heddles or healds, which raise the warp yarns, the shed is created. The filling yarn is inserted through the shed by a small carrier device called a shuttle. The shuttle is normally pointed at each end to allow passage through the shed. In a traditional shuttle loom, the filling yarn is wound onto a quill, which in turn is mounted in the shuttle. The filling yarn emerges through a hole in the shuttle as it moves across the loom. A single crossing of the shuttle from one side of the loom to the other is known as a pick. As the shuttle moves back and forth across the shed, it weaves an edge, or selvage, on each side of the fabric to prevent the fabric from raveling.

- Battening. Between the heddles and the takeup roll, the warp threads pass through another frame called the reed (which resembles a comb). The portion of the fabric that has already been formed but not yet rolled up on the takeup roll is called the fell. After the shuttle moves across the loom laying down the fill yarn, the weaver uses the reed to press (or batten) each filling yarn against the fell. Conventional shuttle looms can operate at speeds of about 150 to 160 picks per minute.

Thanks for stopping by. And thanks to the Swannanoa History Museum of Black Mountain NC for the photo opportunity in their antique display.

No comments:

Post a Comment

Thanks for your comments. Moderation is off (so we'll be checking for spam!)